By Chris Shaul

What is Manufacturing ERP?

Manufacturing ERP (Enterprise Resource Planning) software is a much more complicated system than standard ERP systems. Before we talk about software though we need to understand that Manufacturing ERP also consists of the business processes that it takes to run a manufacturing operation. Unlike distribution or service businesses, there is a complete set of processes that enable the create of value from raw materials. These materials are supported by a supply chain which also needs to be managed.

Setting the software aside, there are inventory processes, shop floor processes, design processes, procurement processes, quality control measures and processes, and order management processes that need to be properly managed in the manufacturing ERP system. Many people have tried to solve the issues related to all of these processes by applying a new software solution to manage the process and have failed.

A blend of people, technology and process factors needs to be evaluated and optimized. If any of these three areas are missing or weak then the overall manufacturing process will not succeed. What will make you successful is improving the processes before you apply a manufacturing ERP software solution.

When evaluating Manufacturing ERP software, it is important that the functional requirements for each of the three factors needs to be evaluated. How will the people be managed and evaluated in the Manufacturing ERP system? How will controls on the machinery and other technology be managed in the manufacturing ERP system? How will the technology enable efficient operations?

A trend in manufacturing over the last decade has been to apply lean manufacturing principles. Essentially, you want to remove waste from a process before automating it. If you do not, you will make the inefficiencies operate faster, creating more in-balances in supply and demand. It really doesn’t matter what you produce in terms of products, or what you utilize as your input raw materials. Lean principles balance out your supply and demand and in doing so, create better throughput. With the advent of Lean Manufacturing principles, many ERP software systems have incorporated a lean thinking into their systems.

Using a combination of Lean principles and common sense, you can work at creating operational efficiencies that will help when you apply any manufacturing ERP software system to help manage the business processes. Bottom line: don’t automate a mess.

Manufacturing ERP Software

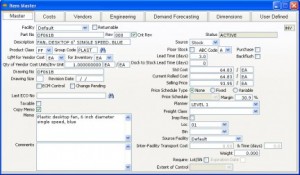

Looking at Manufacturing ERP Software, you need to evaluate how well it manages the manufacturing business functions (such as creating purchase orders, the business processes (such as managing the demand planning process), and how well it manages the data (as in providing efficient access and ease of reporting). That being said, all systems typically have a set of financial modules, a collection of inventory modules, manufacturing modules, and sales and order modules. These various modules each have certain functionalities that help you run the core business.

The differentiation between these various systems is in how well they accommodate the niche business that you are in. If you are a process manufacturer making blends then there is a certain set of Manufacturing ERP systems that work best for you. If you are a machine shop, then another class of Manufacturing ERP solutions work for you. If you are a complex or project based manufacturer, then you will look for different software than others. The good news is that there are ERP vendors that specialize in these different niche areas and others.

Understanding the class of software you want to evaluate is key to creating a short list of vendors. Keep in mind that there is a class of ERP software that fits in as a generalist niche solution. In other words, these software do all aspects of manufacturing fairly well, but do not have a specialty in any certain industry. Often these manufacturing ERP solutions will rely on their value added reseller chain to create add-on modules to fit certain industries. For example, there may be a generalist solution that has a set of 3rd party modules (written in the native tool-set) that provides the process manufacturing functionality.

Things to look for in Manufacturing ERP solutions

When you evaluate Manufacturing ERP software, it can seem overwhelming. There are hundreds of manufacturing ERP software vendors all looking to be the next system at your company. If you step back and look at the industry that you belong to and evaluate the systems based on those that are successful in your industry, you will have taken the first step.

Second, you need to look at those systems that support all areas of your business. If you have unusual requirements make the vendor demonstrate how they will handle these unique functions. Many vendors claim to support various business processes, but when you make them show them in detail, there will be a clear distinction between those that can and those that only think they can handle your requirements.

Thirdly, you should evaluate the standard functions, but do not spend too much time on those things. Being able to cut a check or create a debit memo are pretty standard these days. Rather, have the vendor spend time showing you how they will handle your unique Return Merchandise process or your specialized Quality Management requirements. There is a consulting joke about the fact that “you as a customer are unique just like everyone else.” This is both true and false at the same time. Every business thinks it is unique on the whole. But the reality is that you probably do a majority of the things that most other businesses do. However, there is probably 20 percent of the things you do that make you special and make you successful. You want to make sure that these are the things that you drill down on with the vendors to ensure that you can continue to be special in those areas.

What if you cannot make a decision on a Manufacturing ERP solution?

We know how hard it is to try and make a software selection on your own, but if you want to really be successful and choose the perfect fit software for your organization, you will need to find the right guidelines to help you be successful.

These methods are simple to pick up and they don’t take a lot of learning. You can read how to do it in our free report on ERP Selection, the ERP Software Buyers Guide.

Don’t worry, it is not impossible. Learn more ways on How to Have a Successful Selection Project by clicking on the link.

Article Source: http://EzineArticles.com/?expert=Chris_Shaul

http://EzineArticles.com/?Fundamentals-of-Manufacturing-ERP&id=6289823

![]()